WEIGHING STATION

WEIGHING STATION

networked, intelligent

system scale

Weighing station

IWS 2500

SSC 9200

THE BEST SOLUTION OPTIMIZED FOR:

FRUIT · VEGETABLES · MEAT · FISH · CHEESE

THE BEST SOLUTION OPTIMIZED FOR:

READY MEAL · FRUIT · VEGETABLES · MEAT · FISH · CHEESE

SYSTEMSCALE

Contact us for more information

Highlights &

advantages

of the giveways

maximation

3-12 month

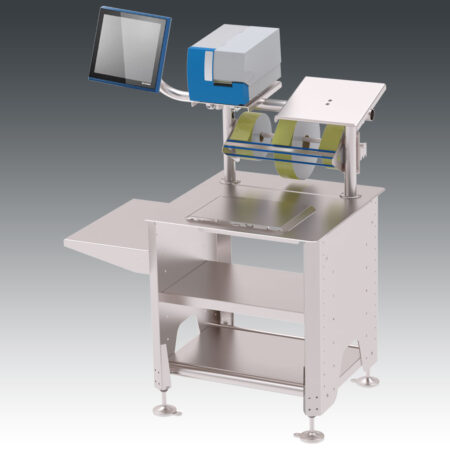

IWS 2500

Reduce wasted goods and maximise productivity at the same time. Excessive filling and overpacking can quickly eat into your profit margin by not only consuming unnecessary product resources, but also increasing transport costs due to the increased weight. With our intelligent IWS 2500 levelling scale, you can optimise the giveaway of the goods to be packaged using dynamic weight limit control.

This allows you to maximise your profits in the shortest possible time. The average return on investment (ROI) is between 3 and 12 months.

Our high-precision and user-friendly mobile weighing stations are impressive across the board. The stable tripod allows the weighing station to be moved quickly and flexibly.

The networked system scale is equipped with an easy-to-use touchscreen and intuitive LED weight display. It displays the weight in the packaging in a language-neutral and easy-to-understand way: “Red=too little”, yellow-orange=”too much” and green=”just right, target weight reached”. Your workers do not have to interpret complicated weight figures. This saves valuable time and enables precise filling of your products.

*** Translated with www.DeepL.com/Translator (free version) ***

The intelligent weighing station can be used for both positive and negative weighing.

Our intuitive foodProcess production control software networks our scales and thus utilises their full potential.

Intelligent weighing station for positive and negative weighing

Levelling or removal weighing can be defined per article

Hygienic and stable tripod construction

Recording of incoming batches and waste quantities

Maximum productivity thanks to intuitive LED display

Optimisation of the giveaway

Dynamic weight limit control

ROI within 3-12 months

Profit maximization

Packing according to WELMEC 6.4 (e-weight) for pre-packed goods

Complete control and registration through the TopControl software

Downloads

Application areas and compatibility

| Software | FoodProcess |

|---|---|

| Packing | Ready Meal, small packaging |

| Area of application | Ready Meal, fruit, vegetables, fish, cheese, meat |

Application areas and compatibility

| Software | FoodProcess |

|---|---|

| Packing | Ready Meal, small packaging |

| Area of application | Ready Meal, fruit, vegetables, fish, cheese, meat |

Downloads

Intelligent weighing solutions and networked processes for maximum efficiency

Intelligent networking

Networked production control with foodProcess

The graphic shows how the TopControl foodProcess software intelligently networks and controls the entire production process.

-

Centralised control: All orders, products and process data can be monitored and controlled in real time in the administration.

-

Intelligent networking: Several scales and workstation systems (such as the IWS 2500) are connected directly to foodProcess via Wi-Fi.

-

Real-time data analysis: production data such as quantities, weight, giveaway and underweight are recorded immediately and visualised in clear dashboards.

-

Process optimisation: Colour coding immediately indicates efficiency (e.g. underweight, overweight, optimally weighed). This allows deviations to be recognised and corrected immediately.

-

Transparency & traceability: All production steps are fully documented – from the workplace to the office.

Mobile structure

The IWS 2500 is a smart weighing solution that is optimised for positive and negative weighing in ready meal production.

-

Control Display: Orders are processed and user guidance is controlled via the control terminal.

-

User registration: Employees register quickly and securely at the terminal using an RFID chip.

-

Weighing platform: The precise scales calculate the optimum weight and minimise overfilling.

-

Tripod design: The mobile, stable, hygienic design enables use in demanding production environments.

-

Wi-Fi connection: The system is directly networked with the foodProcess software solutions via Wi-Fi and supports the requirements of Industry 4.0.

Efficiency through intelligent data integration

The IWS 2000 & IWS 2500 are seamlessly networked with foodProcess. In the office, they can call up real-time data on the entire production process and automatically set the machines on their lines for the order. At the same time, the

production process is efficiently and automatically controlled by the intelligent algorithm in the smart weighing terminals that thinks and learns with you. Limits are adjusted to ensure the best combination of accuracy and speed.

Advantages of IWS solutions at a glance

- Highest precision in weight control

- Increased efficiency through smart data integration

- Reduction of material losses and costs

- Sustainable production through process optimisation

- Simple operation & intuitive user interface