SCALE

SCALE

SMART SYSTEMSCALE

SYSTEMSCALE

IWS 2000

SSC 9200

THE BEST SOLUTION OPTIMIZED FOR:

FRUIT · VEGETABLES · MEAT · FISH · CHEESE

THE BEST SOLUTION OPTIMIZED FOR:

FRUIT · VEGETABLES · MEAT · FISH · CHEESE

SYSTEMSCALE

Contact us for more information

Highlights &

advantages

of the giveways

maximation

3-12 month

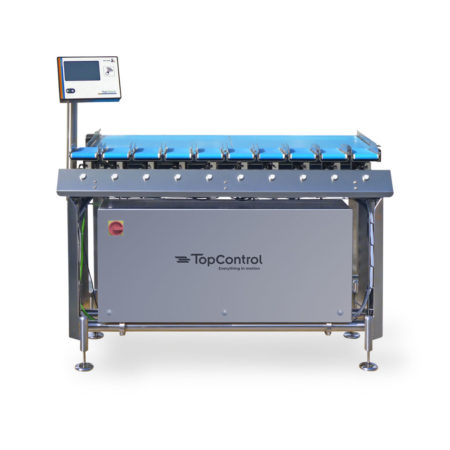

Weighing scale · IWS 2000

Reduce wasted product while maximising productivity. Overfilling and overpacking can quickly eat into your profit margin by not only consuming unnecessary product resources, but also increasing transport costs due to the increased weight. With our IWS 2000 intelligent levelling scale, you optimise the giveaway of the goods to be packaged using a dynamic weight limit control.

This maximises your profit in the shortest possible time. The average return on investment (ROI) is between 3 and 12 months.

Our high-precision and user-friendly bench scale convinces all along the line. The easy-to-use touch screen and intuitive LED weight display shows the weight in the packaging in a language-neutral and easy-to-understand way: “Red=too much”, Yellow=”too little” and Green=”just right, target weight reached”. Your workers do not have to interpret complicated weight figures. This saves valuable time and enables precise filling of your products.

The bench scale can be used as a stand-alone model or in combination with our brand new, intuitive software “foodProcess”.

Maximise giveaway reduction and increase in productivity

Recording of incoming batches and waste quantities

Profitmaximization

ROI 3-12 month

Optimization of giveaway and maximum productivity through integrated LED-display

Optimisation of the giveaway

Dynamic weight limit control

PackingaccordingWELMEC6.4/℮ forfinishedpacks

Intuitive touch display

Efficientstafftimerecordingwithintegrated RFID reader

Complete control and registration through the TopControl software

Downloads

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Fruit | Berries, Fruit salad, Table grapes |

| Vegetables | Basil, Beans, Carrots, Chives, Ginger, Lettuce, Mushrooms, Onion, Parsley, Peppers, Pumpkin, Tomatoes, Zucchini |

- Maximise giveaway reduction and increase in productivity

- Integrated LED indicator

- Profitmaximization

- Individual adjustment of levelling or extraction weighing definable per article

- Packing according WELMEC 6.4/℮ for finished packs

- ROI within 3-12 months

- Complete control and registration through the TopControl software

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Fruit | Berries, Fruit salad, Table grapes |

| Vegetables | Basil, Beans, Carrots, Chives, Ginger, Lettuce, Mushrooms, Onion, Parsley, Peppers, Pumpkin, Tomatoes, Zucchini |

Downloads

Highlights of the levelling scale

Display

Workers log in via the intuitive display using an RFID chip. The exact time and weight data are recorded for each order and then analysed in the appropriate software. This also guarantees the traceability of all packs with detailed data.

Weighing platform

Depending on the area of application, the weighing platforms can be choosen in aluminium or inox in the sizes 200 x 300 mm and 300 x 400 mm with different weighing ranges (see technical details).

Stand and wall mount

The terminal can be mounted in different ways. There are small, middle and high stands on which the terminal can be mounted in landscape mode, centred or sideways to the platform.

Upgrade your machines with our software solutions

TopControl’s software solutions convince through their functionality and intuitive operation. As a result, you always have an overview of your production. Giveaway optimisation, productivity growth, cost reduction and an efficiency optimisation are just some of the benefits you will have by using TopControl machines with the right software. Optimal resource management with complete time and data recording of the workplaces results in a significant increase in profits. Learn more about our software solutions.