WEIGHING

TABLE

TABLE

INTELLIGENT

INTELLIGENT

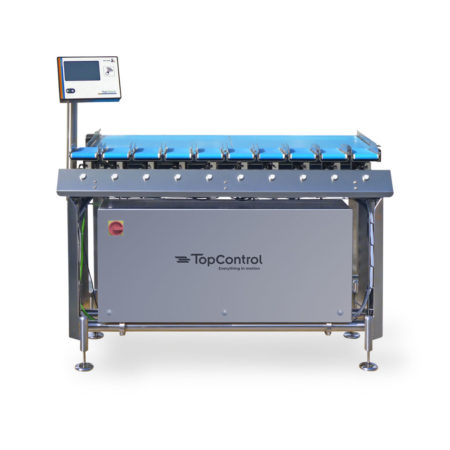

WEIGHING TABLE

IWS 3000

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard Lorem Ipsum has been the industry’s standard

THE BEST SOLUTION OPTIMIZED FOR:

vegetables, fruit, meat, fish, cheese ....

Contact us for more information

Smart lighting

Integrated into the Covid-compliant Plexiglas partition incl.

customer logo, it ensures optimal position and brightness.

2x 2.550lm (5.100lm)

Highlights &

advantages

technology

intelligent scale

hygienic workstations

Smart weighing table · IWS3000

TopControl’s new smart weighing tables can be used as a stand-alone unit or integrated into a customer-tailored packing line, making the packing and repacking process easier than ever before.

With the integrated system scale, which uses an LED indicator with colour scale to show the appropriate weight or the missing or excess quantity, it is easy to fill the correct packaging quantity into the punnets in the shortest possible time and guarantee a minimum giveaway.

The tables are made of robust and hygienic stainless steel and comply with the standards for the food industry. Ergonomically designed for ease of use, they can be adapted to the workers so that working on them is easier and faster.

The weighing tables represent a significant increase in efficiency in the packaging process. Other optionals such as waste bins in various sizes, daylight LED lighting and flexibly adjustable box storage guarantee the highest quality to meet your requirements.

The high accuracy of the scales increases packaging speed with minimal staff management. This noticeably reduces costs and increases profits. Connected with the TopControl software all weights and staff times are completely recorded, for efficient evaluation and reporting.

Ergonomic, robust & hygienic workplaces

Recording of incoming batches and waste quantities

Profitmaximization

ROI 3-12 month

Maximum packaging speed through intuitive LED indicator

Optimisation of the giveaway

Suitable for transport and small packaging

Stand-alone and integrated in packing lines

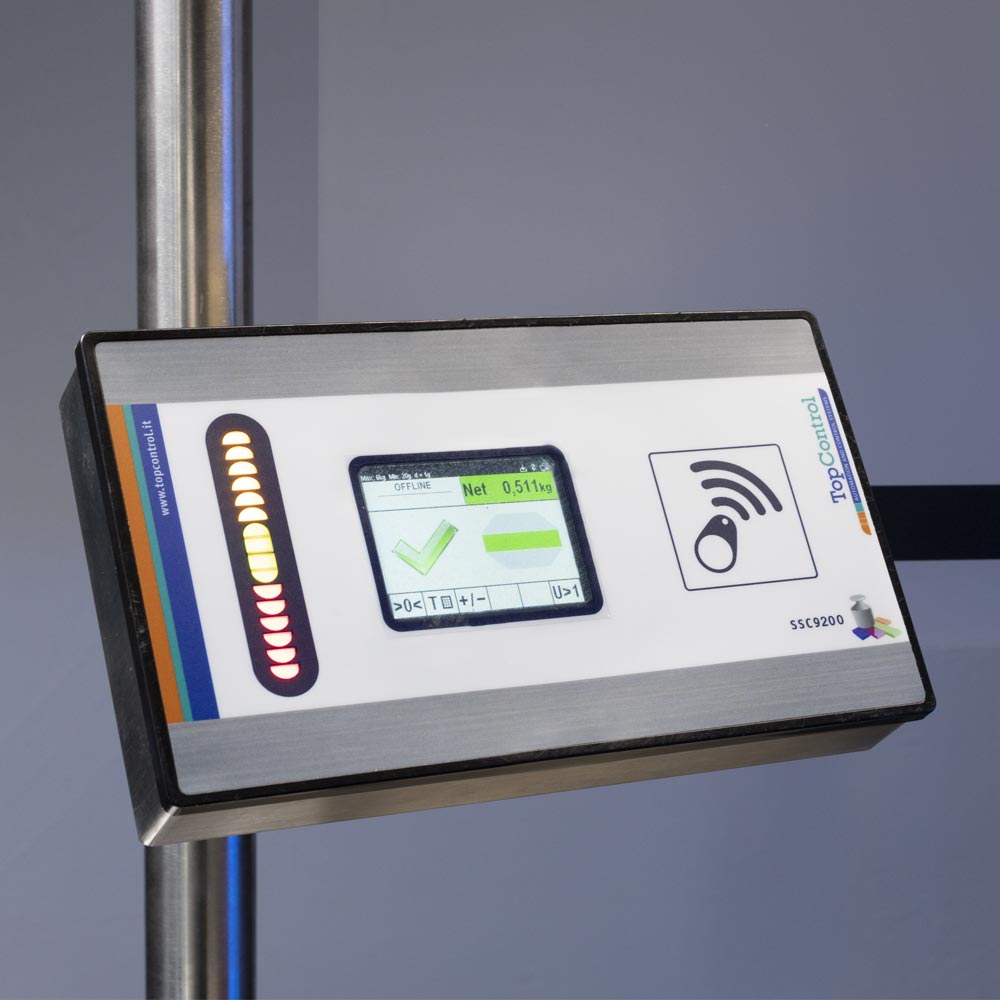

Intuitive touch display

Efficientstafftimerecordingwithintegrated RFID reader

Complete control and registration through the TopControl software

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Downloads

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Fruit | Berries, Fruit salad, Table grapes |

| Vegetables | Basil, Beans, Carrots, Chives, Ginger, Lettuce, Mushrooms, Onion, Parsley, Peppers, Pumpkin, Tomatoes, Zucchini |

- Maximum reduction of the giveaway and maximum increase of the productivity

- Integrated LED indicator

- Profitmaximization

- Individual adjustment of levelling or extraction weighing definable per article

- Packing according WELMEC 6.4/℮ for finished packs

- ROI within 3-12 months

- Complete control and registration of weight and performance data through the TopControl software

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Small packaging, Transport packaging |

| Application | Cheese, Fish, Fruit, Meat, Vegetables |

| Fruit | Berries, Fruit salad, Table grapes |

| Vegetables | Basil, Beans, Carrots, Chives, Ginger, Lettuce, Mushrooms, Onion, Parsley, Peppers, Pumpkin, Tomatoes, Zucchini |

Downloads

Highlights of the levelling scale

Display

The workers log in via the intuitive display using an RFID chip. Integrated into the WLAN network, each scale transmits the weight data and personnel time to the central TopControl software. This also guarantees the traceability of all packages with detailed data.

Integrated system scale

The levelling scale optimises the giveaway of the goods to be packed. Integrated in the network, the weights are recorded directly in the central TopControl software, thereby increasing yields by avoiding unnecessary overcrowding. The high accuracy of the scale and the intuitive operation allow considerable savings in time and product costs.

FUNCTIONS

- Dynamic control of weight limits, levelling or removal weighing definable per item

- Recording of incoming batches and waste

Ergonomic box storage

In order to ensure fast and optimised work, height-adjustable box trays can be attached to the weighing tables. These are adapted to the box heights. The ergonomic adjustment prevents premature fatigue of the workers.

An additional box storage can be mounted under the table.

The workers always have the full boxes at hand.

Upgrade your machines with our software solutions

TopControl’s software solutions convince through their functionality and intuitive operation. As a result, you always have an overview of your production. Giveaway optimisation, productivity growth, cost reduction and an efficiency optimisation are just some of the benefits you will have by using TopControl machines with the right software. Optimal resource management with complete time and data recording of the workplaces results in a significant increase in profits. Learn more about our software solutions.