PRODUCTS

Process optimizing

solutions for food industry

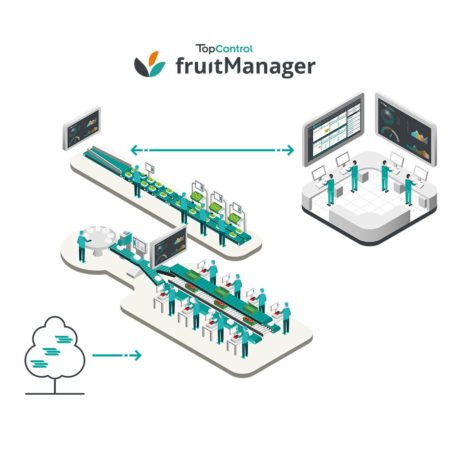

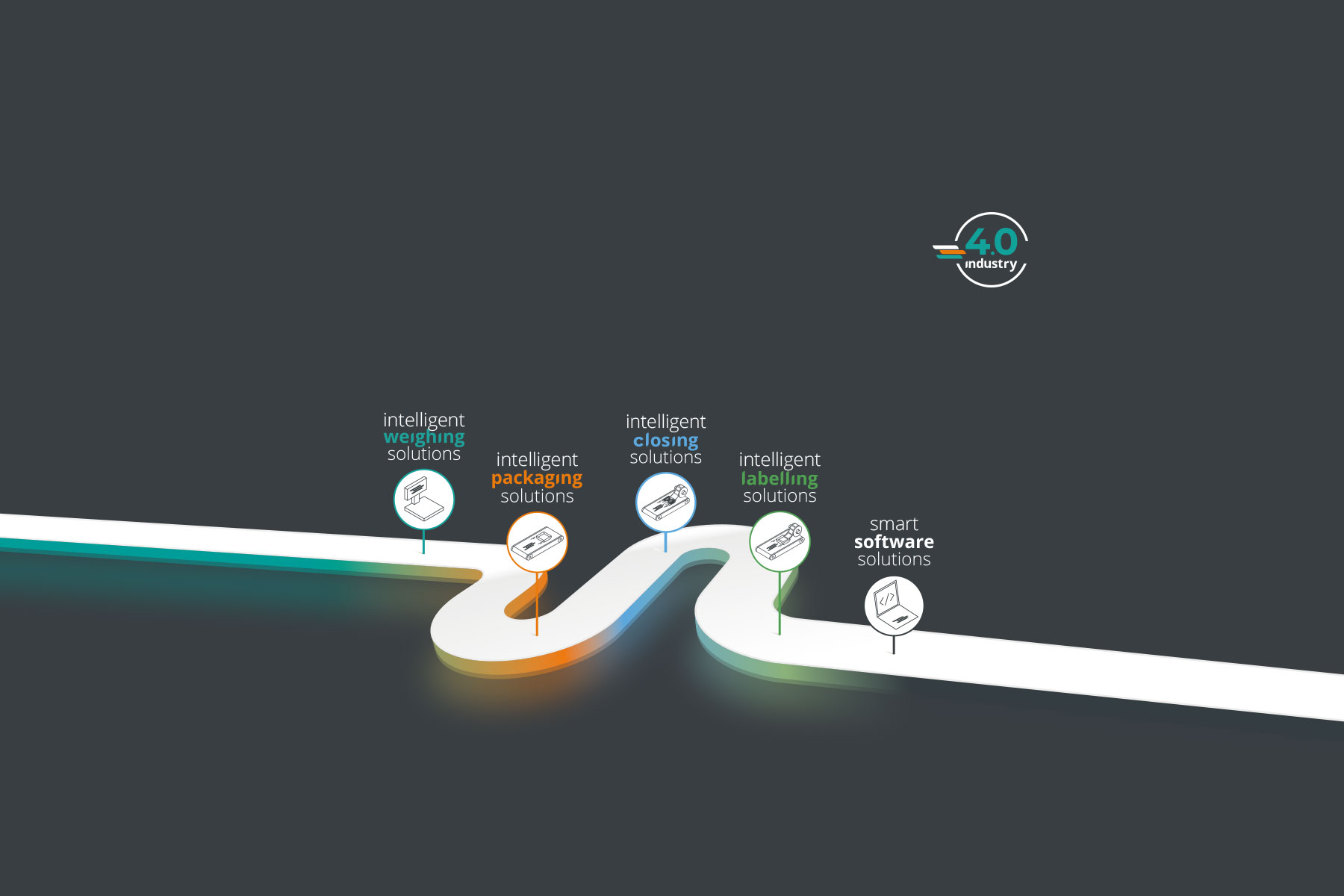

Our products for your production

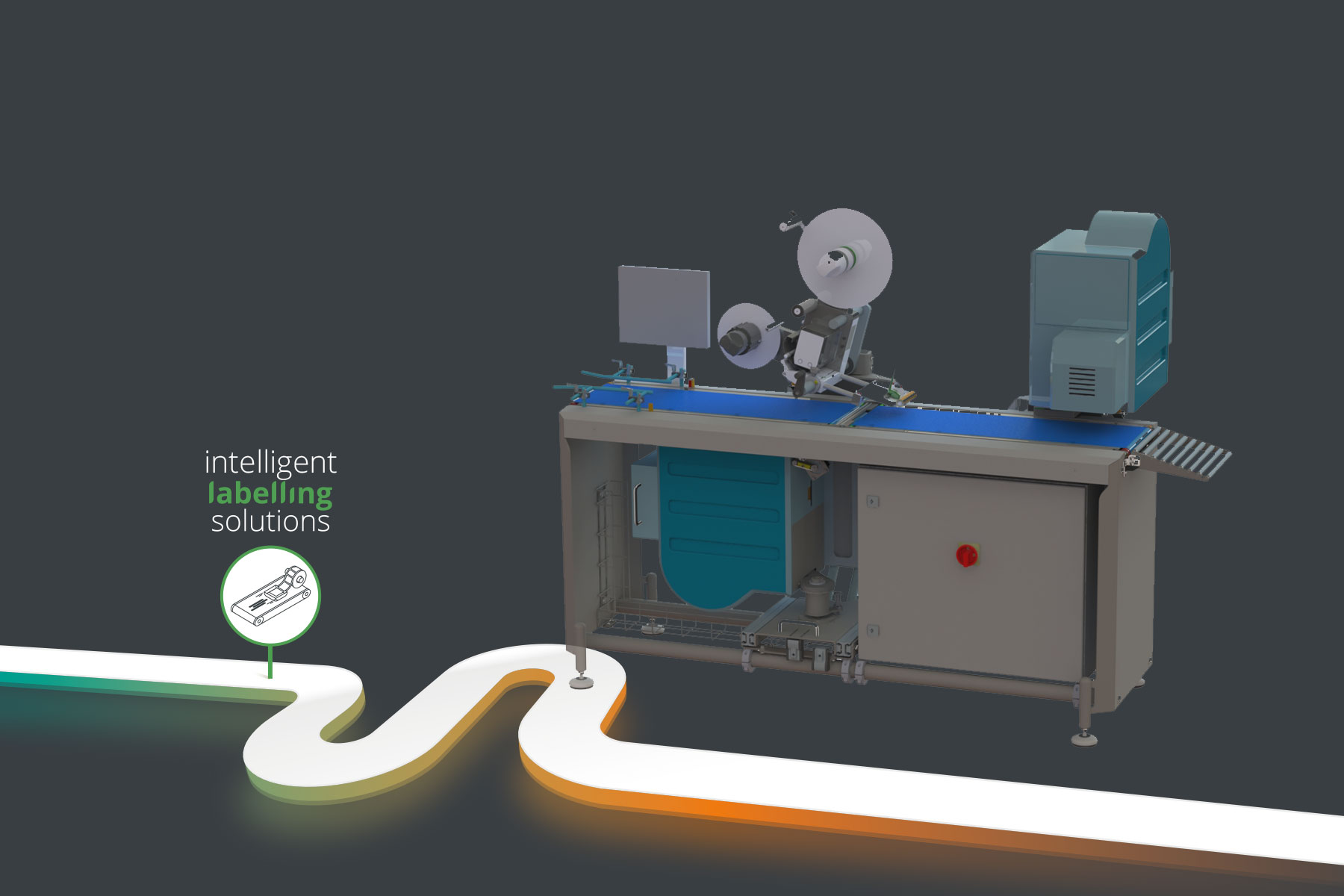

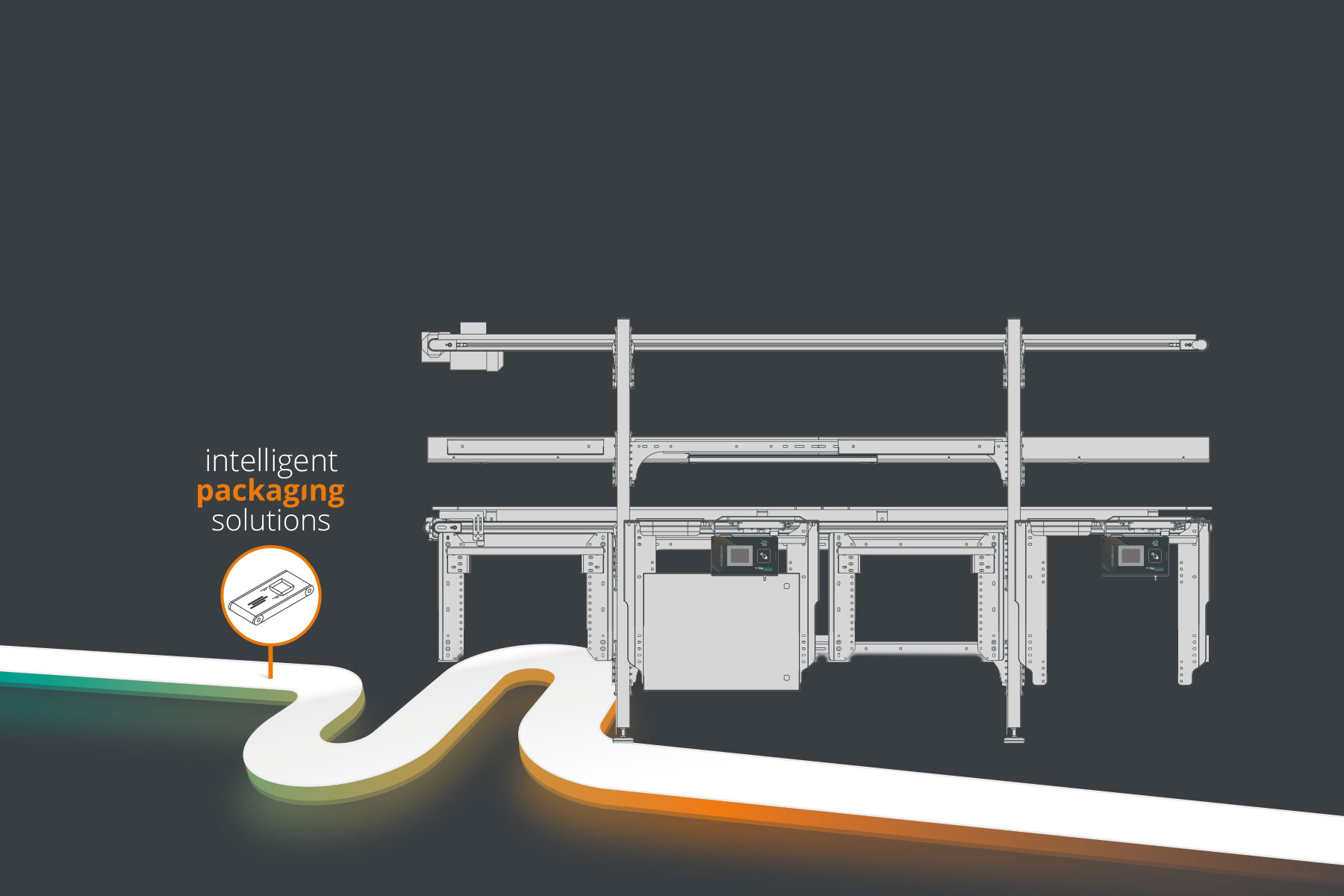

With TopControl machines and software solutions, you are always one step ahead: Our automation and system solutions optimise your usual processes with the use of innovative technology. Our product portfolio ranges from precise combination weighers to high-performance labellers and efficient packaging lines. With our sophisticated IT solutions, your processes are handled in an even smarter and networked way.