PALLET

LABELLER

PALLET

LABELLER

GPH MAXX 9000

Highlights &

advantages

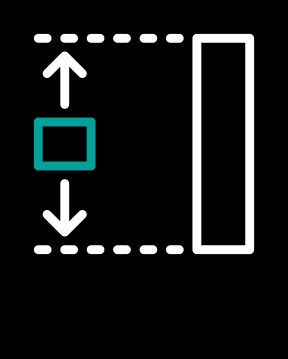

& variable height

service

labelling

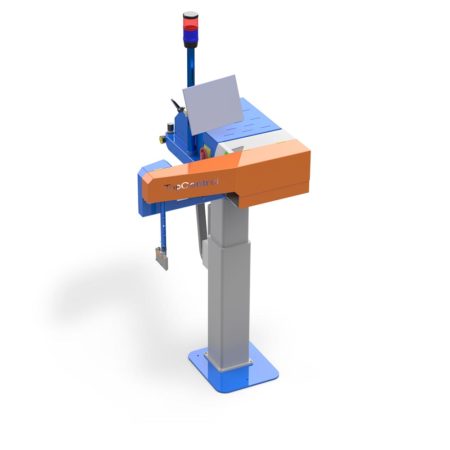

Pallet labeller GPH MAXX 9000

The GPH MAXX 9000 is a pallet labeller with automatic height and side adjustment. This offers the possibility to la-bel on three sides of a pallet in different heights. Due to its high functionality and performance it is perfectly suited for applications in the industrial and logistics sector. The application of labels is guaranteed in a secure and precise way on different surfaces.

Large pallets, small effort with the GPH MAXX 9000

Labelling of three sides and different heights on a pallet

Control of one or two pallet labellers

Printing of UNICODE fonts

Easy change of label roll

Scanner connection

Remote Service

Possibility to connect a weighing platform (verifiable) to record the weight

Flexible fields of application as standalone-labelling unit

Integration in the TopControl FruitManager®

High speed

Downloads

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Pallets |

- Labelling of three sides and different heights on a pallet

- Control of one or two pallet labellers

- Printing of UNICODE fonts

- Easy change of label roll

- Remote Service

Application areas and compatibility

| Software | FoodProcess, Fruitmanager |

|---|---|

| Packaging | Pallets |

Downloads

The fully automatic pallet labeller increases the efficiency of the packaging process

Adaptable

The position of the labels is variable. This offers the possibility to la-bel on three sides of a pallet in different heights.

It is also possible to connect an optional scanner and / or scale for recording the weight.

Our software solutions for 360° smart processes

All our machines are compatible with our software solutions, making them even smarter. The labeller can be connected to the FruitManager so that you have a precise overview of all processes. You can control them fully automatically and track the production steps. With the TopControl FruitManager solution, your company saves time and money while increasing efficiency and quality in the production process.